Right before a newly made car or truck is sent to a dealership, it normally joins hundreds of other individuals in a significant storage lot where it can sit for days or even months.

Handling these a lot necessitates many guide, time-intensive duties: attendants need to get started each and every motor vehicle, park it securely in a selected spot, continue to keep observe of its place and be in a position to obtain it simply for distribution when desired.

Car or truck remarketers, airports, auto rental products and services and quite a few other corporations that demand high-quantity vehicle storage and straightforward retrieval share these exact same issues. In the long run, handbook auto parking success in inefficient area and labour utilization, hazard of incident and injury to attendants, and burning of gas.

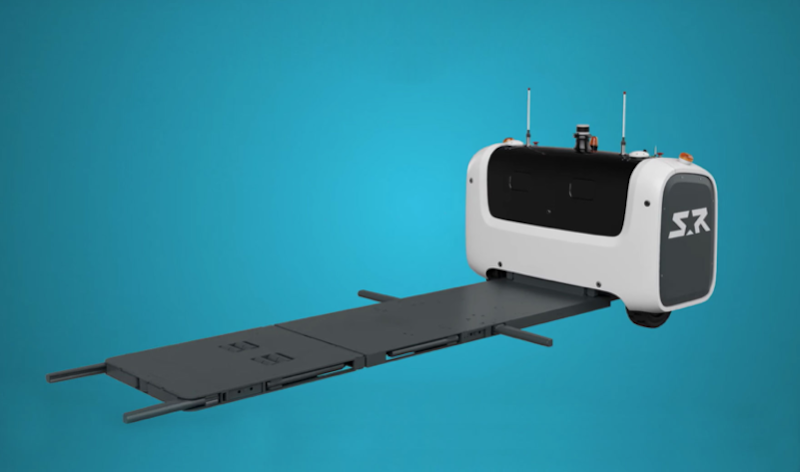

France-centered Stanley Robotics, a company of vehicle storage logistics robots, hopes to improve all that, providing a self-guided, vehicle-carrying platform that finds a car or truck, lifts it, moves it carefully, and parks it in an allocated space.

When the robot arrives at the car or truck, light detection and ranging (LiDAR) sensors detect its place, the placement of the wheels, and the length amongst them, and slides the system beneath.

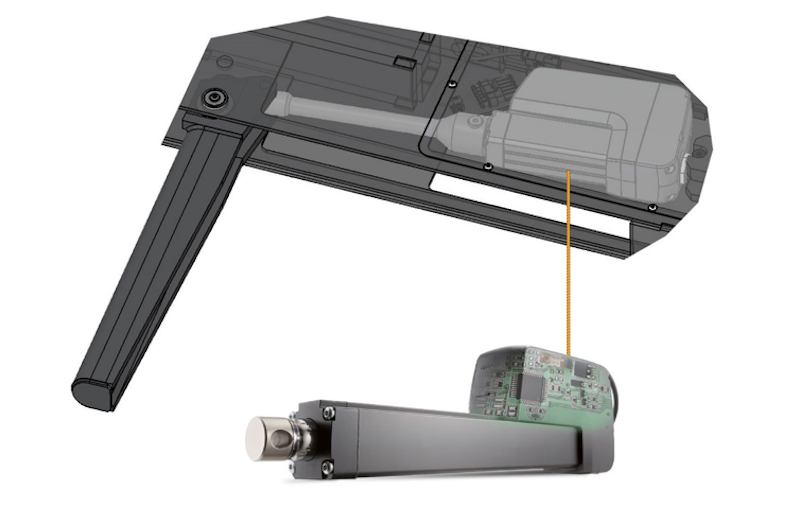

When the car or truck is aligned on the platform, electric powered linear actuators from Thomson Industries assist to protected the motor vehicle on the platform and lift it.

Converting to electric powered

When Stanley Robotics established its 1st-era robotic in 2015, engineers made use of hydraulic cylinders to move the platform’s two arms, or pliers, into location. Hydraulics exhibited various negatives, nevertheless, primary them to check out electric actuators for their future-generation product or service.

Thomas Ravasi, senior mechanical engineer at Stanley Robotics, says: “There have been leaks with hydraulics they had been higher maintenance. Their high load potential was an gain, but they are slower than electric powered actuators and needed added elements these kinds of as hoses and pumps.

“They are also a lot more durable to combine within a robotic than electric powered actuators. Hydraulic techniques also consume additional energy, which is important because we run on battery electrical power and need to have to translate as significantly of that into motion as achievable.”

Stanley Robotics chosen Thomson Electrak High definition electrical linear actuators dependent on considerable efficiency benchmarking against competitors, integration screening on 3D CAD style systems and many calculations.

Centered on this investigation, Stanley Robotics concluded that the Thomson electric actuators would fulfill their needs for securing the car or truck on the system, lifting, intelligence, climate resistance and energy use.

Securing the auto whilst in movement

In advance of lifting the vehicle, it will have to be secured on to the system. Stanley Robotics accomplishes this with pliers that close in beneath each tire. When the robotic 1st slides the platform beneath the car or truck, all pliers except the two closest to the robot head are retracted so that the platform can crystal clear the width of the wheels.

The two pliers closest to the front wheels under no circumstances go and hence are not actuated. When the robotic senses that the front wheels are in make contact with with the fastened pliers, the actuators extend the two pliers in the adjustable rear component and shift them backwards until finally they speak to the front of the rear wheels.

As soon as it confirms the pliers are in make contact with with the fronts of all the tires, the robotic indicators the actuator to rotate the remaining four pliers to grip all the wheels. For this critical operate, Stanley Robotics utilizes six Electrak Hd actuators.

Eric Cabrol, Stanley Robotics head of robot engineering, suggests: “When we lift the car or truck, all its fat rests on the pliers, and the load puts stress on the actuator inside of the platform, which attempts to near the pliers inside of the platform.

“The superior static load capacity of electric powered actuators, nonetheless, allows them to operate like a brake to continue to keep the load in the ideal place.”

Cabrol says: “We use the capacity of the actuator to end on its personal.

“The application asks the actuator to open up the pliers as a lot as doable and as they get hold of the wheels, the actuator will increase the grip till it reaches its optimum capability and stops automatically.

“Our embedded software tracks all of this by checking recent intake and sensing the angle of the pliers. If the angle is open sufficient when the existing exceeds a specified setpoint, the procedure assumes that the tire grasp is satisfactory.”

As soon as the wheels are locked in position, two Electrak Hd actuators increase the system approximately 120 mm off the floor.

A smarter option

Electrak Hd actuators aspect onboard electronics, which enable them to take part in programmed sequences and converse information with other actuators and devices.

Cabrol suggests: “We created the software program that we embed in the technique. Integrating this with our sensor architecture allows us to compute the motions that will need to be finished and tells the actuators what to do.

“Our Laptop sends messages via Ethernet, then Ethernet signal CAN converters relay those people messages to the actuators. The Thomson wise actuators present all this capability furthermore exact responses on their placement alongside their stroke. With a hydraulic actuator, we would have to add that.”

Battling the features

Thomson Electrak Hd actuators can function in temperatures ranging from -40°C (-40°F) to +85°C (185°F). The higher conclusion of the temperature assortment is particularly important since much of the robot’s action is carried out on blacktop, which absorbs warmth. Cabrol claimed they have recorded temperatures up to 60°C (140°F).

“The Electrak HD’s IP rating is extremely desirable,” said Cabrol. “We have witnessed scenarios in which the robotic platforms ended up entirely submerged. Even though, we would under no circumstances run them although submerged, of study course, we do want them to return fully operational when the drinking water goes down.”

All billed up

Thomson actuators’ ball screw technological innovation is extremely strength economical. Operators can transfer far more cars on a solitary demand with electrical actuators rather than with hydraulics.

Cabrol suggests: “Because the electric actuators do not need to be jogging all the time, we shed a lot less battery electrical power that way.”

But at the similar time, he states that some heaps run the robots 24/7, and the battery efficiency will help there as effectively.

Velocity and operational efficiency

Most high-quantity parking heaps impression their operators’ bottom line, so the more quickly the actuators can support park a lot more automobiles in considerably less place, the more beneficial they are to the ton house owners and administrators.

Electric powered actuators provide more rewards in this regard mainly because they enable a number of actuators to run simultaneously, as a substitute of in sequence, as most hydraulic alternatives would.

Cabrol says: “Our robots can boost place utilization in most storage parks by up to 50 per cent.

“We can park autos closer together simply because we do not have to open the doors. We can simplify access lanes mainly because our program appreciates precisely where by each and every automobile is and when it requirements to get in and out. And we do it devoid of owning to commence up the automobile, push it and take in fuel, which has implications for reducing the carbon footprints.”

As a result of their blend of static power, intelligence, sturdiness and performance, Thomson Electrak Hd electrical linear actuators have demonstrated their price to Stanley Robotics’ auto storage and retrieval systems and glance to carry on conference their long term requirements.

Main picture: Stanley Robotics robot head with car or truck loaded on system. Thomson actuators rotate plier arms to grip tires to wheels that retain vehicles from sliding off the system though in movement.

More Stories

Tips for Negotiating the Best Deal When Selling Your Car

5 Women That Shaped the Automobile and the World Around It (and Us)

Automobile retail sales see double-digit growth in February on robust demand