Although better known for his principles of production line manufacturing which introduced affordable motoring to the world, Henry Ford also created an aviation legacy for himself that changed how the world would view passenger air travel for the future.

An engineer and inventor at heart

Henry Ford is not a name closely associated with famous aviation pioneers. Only a handful of Ford-built aircraft remain today, most on static display in museums. Yet Ford’s contribution and influence on commercial aviation came at a critical time for the industry.

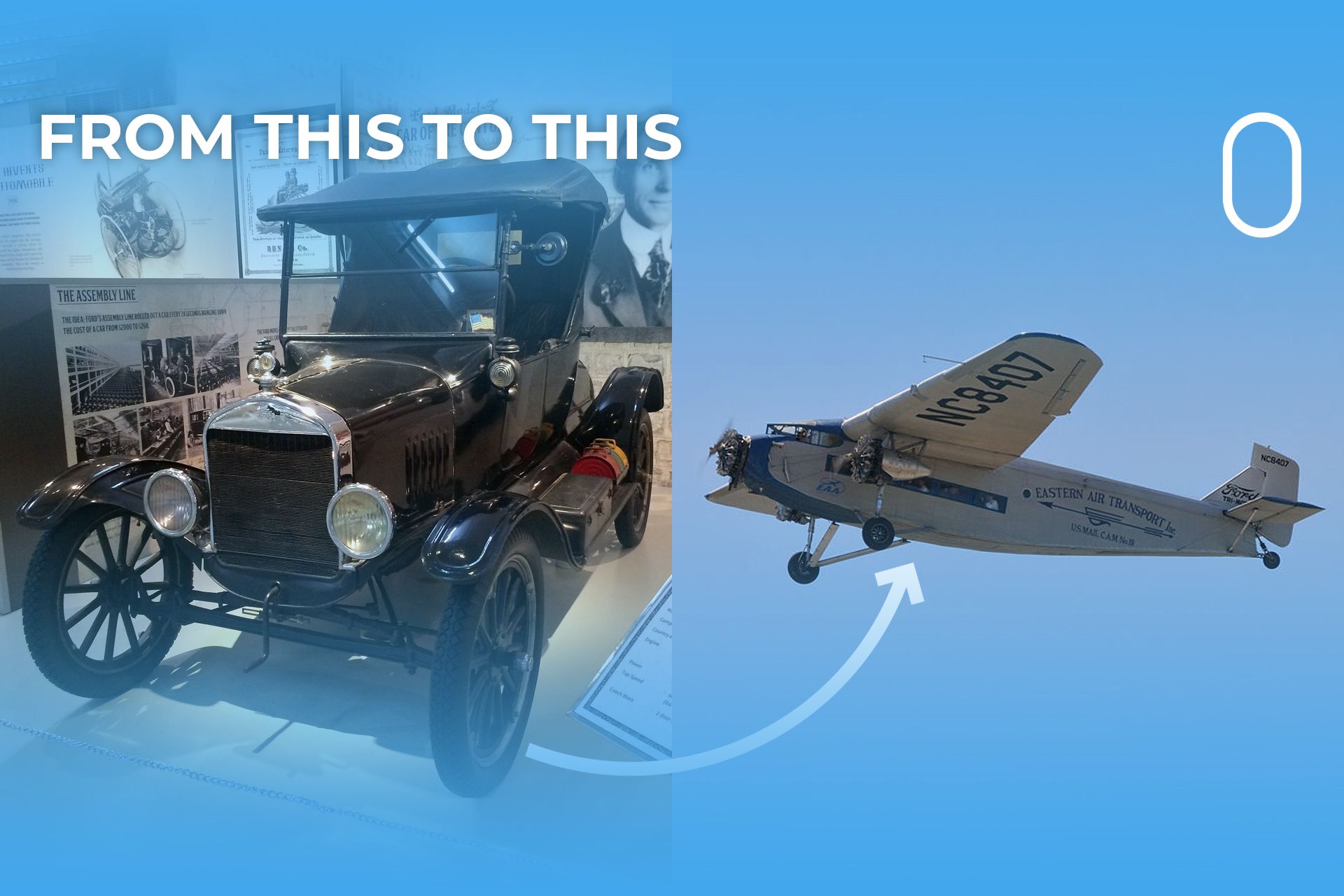

Thanks to his legendary Model T automobile and its well-earned reputation for reliability, in the 1920s, the general public got its first view of Ford’s venture into aircraft design and manufacturing. His contribution signposted the way to a time when passenger air travel would be considered safe for all.

Born in 1863, Henry Ford became interested in many forms of engineering and machinery as a young man. In 1896, he completed his first ‘car’ – a basic four-wheeled vehicle with a 4-cycle engine. However, Ford always set his sights on something much more than producing such simple vehicles as this.

Where it all began – the Ford Model T

When he formed the Ford Motor Company in June 1903, Ford pledged to build a motor car for the general population. The first Model T (known as the ‘Tin Lizzie’) rolled out of his factory in October 1908. Within the walls of that factory, Ford conceived and perfected a system of a constantly moving production line, a process emulated in factories and assembly plants worldwide to this day.

By 1914, Ford’s production line turned out a new automobile every 93 minutes. By 1918, over 50{7b5a5d0e414f5ae9befbbfe0565391237b22ed5a572478ce6579290fab1e7f91} of the cars in the United States were Model Ts. Nearly 17 million of these automobiles were sold in the next two decades. Ford had fulfilled his pledge by bringing motorized private transport within the price reach of the average American family.

With the domination of the US automobile sector sewn up, Ford as an innovator, harvested his other interests. One such interest became a reality in 1909 when Ford installed a Model T engine into a replica Blériot XI bi-plane. Although this venture failed, it paved the way for what was to come next for Ford.

Ford enters the aviation industry.

After the United States entered World War I, the Ford Motor Company, along with other auto manufacturers, went on to build nearly 4,000 8- and 12-cylinder Liberty aero engines. Ford engineers also developed a 2-cylinder, 40-hp engine that could be mass-produced for US$40 each to power the secret Kettering Bug, an unmanned flying bomb with a 200-pound warhead.

Ford later invested in the Stout Metal Airplane Company, owned by William B. Stout. This company specialized in designing and producing all-metal planes, beginning with the four-passenger, single-engine Stout 1-AS Air Sedan.

This early passenger aircraft was followed by the 2-AT Air Pullman, the first eight-passenger high-wing, single-engine monoplane, and the direct ancestor of the Ford Tri-Motor series of aircraft.

Following his involvement with Stout, Henry Ford decided that his company should become more involved in helping to develop commercial aviation. He foresaw a great need for more US airfields to be built for commercial purposes.

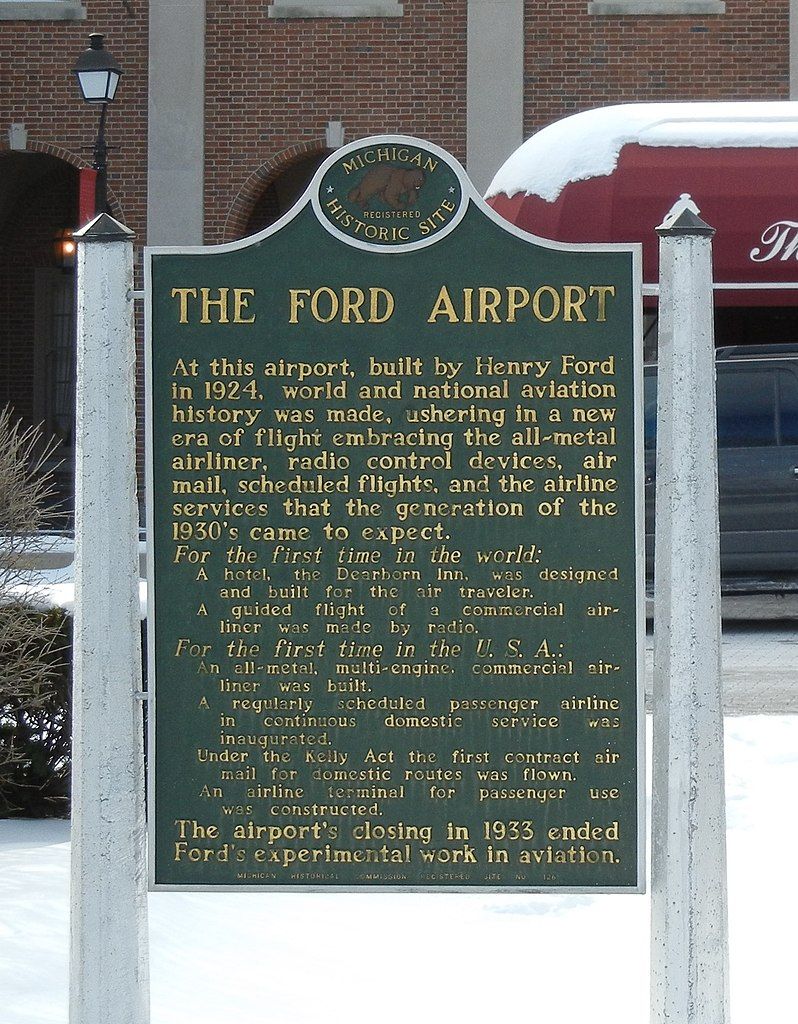

Ford as an airport developer

In 1925 Ford Airport was laid out in farmland near the Ford headquarters at Dearborn, Michigan, USA. In addition, the Fords built a large facility where Stout continued his development work on all-metal aircraft. The name “FORD” was written in 200-foot letters with white crushed stone. This allowed pilots to identify the airport from the air easily.

At first, the airport was widely praised as one of the best in the world, but it required improvement after the tail skids of many of the aircraft of the age damaged the grassy landing strips.

In December 1928, Ford Airport got the first concrete runway in the world. That was soon followed by a passenger terminal, a weather station, and the Dearborn Inn for transient travelers, all of which became models for other airport developers worldwide. This was just months after the world’s first purpose-built passenger terminal had opened at Croydon Airport, UK.

A growing interest in developing commercial air transport

As public interest in aviation increased after WWI, so did Henry Ford’s awareness of commercial aviation’s potential for carrying large numbers of passengers. He purchased the Stout Metal Airplane Company outright, subsequently becoming a Ford Motor Company division in July 1925. The airport facilities were then dedicated to further developing and producing the Tri-Motor series of planes.

Ford used the first Tri-Motors (known as the ‘Tin Goose’) built at the new factory to establish the Ford Air Transportation Service in April 1925. The purpose of this outfit was to carry Ford company mail and freight on scheduled flights between Dearborn and the main US Air Mail field near Chicago, Illinois.

With the commencement of this service, the first air transportation service operated for the benefit of a commercial company was born, along with the first air freight service to maintain a regular schedule.

A second route was established in 1926 linking the headquarters with the company’s operations in Cleveland. This service was later extended to Buffalo in 1927. By that time, more than 1,000 successful flights had been made, with payloads of up to 1,500 lbs per flight. The Ford Air Transportation Service continued to operate as a business until August 1932.

When private operators began taking over mail routes from the US Post Office Department in 1926, Ford was the first company awarded a contract to fly the mail between Detroit, Chicago, and Cleveland.

According to the Curtiss Aeroplane and Motor Company president, CM Keys, Ford’s operations represented “the starting point of organized commercial aviation in this country.” Meanwhile, an editorial in a Detroit newspaper commented that “Ford’s entrance into aviation means progress in three departments: commercial flying, passenger flying, and national defense.”

Introducing the Ford Tri-Motor

After Ford purchased Stout’s assets, he announced plans to begin building planes at the rate of one every two weeks. This would be possible as he would apply the Ford system of progressive production of automobiles to aircraft manufacturing for the first time.

A larger factory was built to turn out the ubiquitous Ford Tri-Motors. The 4-AT and 5-AT models were particularly popular with the burgeoning airline companies, and production was increased within three years to one plane every other day. These airplanes were snapped up as the demand for air travel began to outstrip what the fledgling airlines could provide.

The US Army, Navy, and Marine Corps also purchased Ford Tri-Motors for use as transports. Ford also produced a bomber version, although its design was judged unsatisfactory, so the US Government never ordered it.

Pilot Bernt Balchen’s 1928 flight to the South Pole in a 4-AT became one of the Ford Tri-Motor’s crowning moments. That same year Balchen also flew a 4-AT to rescue the three crewmen of a German Junkers monoplane forced down in Newfoundland following the first-ever east-to-west transatlantic flight.

Development of the Tri-Motor concept

The period between 1928 and 1929 were prime production years for Ford Tri-Motors. By then, Ford had come to believe that aircraft manufacturers should develop planes with greater passenger capacity, so he asked Stout to design a transport capable of carrying an unprecedented 100 passengers.

Stout cautioned Ford that such a large plane was not feasible at the time, explaining that it would be much more practical to build a smaller one first. Ford reportedly replied,

“No, I would rather build a big plane and learn something, even if it didn’t fly, than to build a smaller one that worked perfectly and not learn anything.”

Ford eventually yielded to Stout’s sensibilities, and instead of a giant transport, Stout designed the 10-A, a 32-passenger, four-engine plane with compartments similar to the US Pullman railroad cars. This plane was powered by two 575-hp Pratt & Whitney Hornet engines mounted in the wings on top of the center section. Although the 10-A was never built, it eventually evolved into the 14-A Tri-Motor.

The 14-A had seats for 32 passengers, a smoking room, two lavatories, and a galley. However, it collapsed during taxi tests and never flew, marking the end of the Ford Tri-Motor line. Other Tri-Motor models included the 6-AT, 7-AT, 9-AT, 11-AT, and 13-A, all modified 4- and 5-AT airframes but equipped with different engines.

Hard times call for a new direction.

At this point, Ford recognized the technological leap Douglas was making with its twin-engine DC-2s and DC-3s and Boeing with its 247. With the Great Depression in full flower, he decided that the Tri-Motors era was over. He would subsequently concentrate full-time on automobile production to keep his company alive.

Before the Depression gripped the country, Ford had launched an initiative that helped the aviation industry at a critical time. Harvey Campbell of the Detroit Board of Commerce had proposed an air tour to gain increased public acceptance of the automobile.

Henry Ford adopted the idea and organized the Ford air tours in 1925 to stimulate interest among civilian constructors and pilots, and to end the dominance of the military and the emphasis on stunt flying, but to demonstrate the reliability of travel by air on a predetermined schedule regardless of intermediate ground facilities.

Cash prizes and a large gold and silver Ford Reliability Trophy were donated “to encourage the up-building of commercial aviation as a medium of transportation” and help erase aviation’s once-reckless image.

One of the side benefits of the air tours was a program to encourage Ford automobile dealers along the tour routes to paint the names of their cities on the roofs of their facilities, along with an arrow pointing due north to aid navigation from the air. However, the arrows were later repainted to point to the nearest airport.

That concept was further promoted by the Guggenheim Foundation and later adopted in a Department of Commerce program. By the end of 1929, about 6,000 US communities had painted town identification signs on rooftops and water towers, many of which are still visible today.

The Depression affected Ford adversely, as it did all auto and plane manufacturers. The last 212 Stout/Ford aircraft built were two Ford Tri-Motors delivered to Pan American Airways in May 1933.

Despite their disappointment in winding down the Tri-Motor production line, the Fords continued promoting commercial aviation. They placed advertisements for Ford Tri-Motors in major newspapers and magazines that stressed the safety, comfort, and reliability of modern aircraft when they were flown by responsible pilots.

An editorial in Aero Digest claimed that Ford’s advertising had “done more to popularize flying among the reading public than all the stunts that have ever been performed.”

WWII brings further opportunities

Upon the commencement of the Second World War, Henry Ford spotted an opportunity. He quickly restructured the company to help aviation again, just as he had done during World War I. The company accepted contracts to produce wartime equipment for Great Britain and France beginning in 1940.

He also directed the construction of the world’s largest factory, with 5 million square feet of space, at Willow Run near Ypsilanti, Michigan, to produce Consolidated B-24 Liberators for the US Air Force.

The key to mass production was tooling, and Ford had carried the technique further than any other company in the world with his system of progressive assembly lines. Ford subsequently set an eventual production goal of one B-24 Liberator per hour.

At the end of 1943, the 1,000th Liberator rolled out. The last of 8,685 Ford-produced B-24s was completed in June 1945, marking the end of the Ford Motor Company’s ventures in aircraft production.

Ford’s aviation endeavors are possibly best remembered for that outstanding wartime accomplishment, which set production standards for aircraft manufacturing. However, it should also be remembered that Ford also turned out 4,000 Pratt & Whitney R-2800 engines, 4,202 Waco CG-4A Army gliders, and 87 of the larger CG-13As.

Ford engineers also built an advanced altitude chamber for testing equipment and flight personnel at low temperatures and high altitudes. Additionally, 2,400 jet engines were assembled to power Army Air Forces and Navy missiles for use against Japan.

Lastly, Ford also produced hundreds of airplane drop tanks, aircraft generators, and cockpit instruments and maintained a school to train 50,000 military aircraft maintenance personnel.

In memoriam

Henry Ford died at the age of 83 on April 7th, 1947, having witnessed the bombers his company produced make a significant contribution to the US war effort. Although Ford Tri-Motors have won a permanent place in history for their sturdy reliability, Henry Ford did not receive any honors for his aviation contributions during his lifetime.

However, just as Ford’s Model T had opened up private car ownership to the masses, many people’s first taste of airline travel was courtesy of a Ford Tri-Motor.

Photo: Joe Hunter/Shutterstock

Ford’s remarkable aviation accomplishments were finally recognized in 1984 by the United States National Aviation Hall of Fame. This enshrined him for his outstanding contributions to aviation through his leadership in developing and mass-producing commercial and military aircraft and engines.

Sources: Ford Motor Company, Biography.com, Thoughtco.com, Entrepreneur.com

More Stories

Tips for Negotiating the Best Deal When Selling Your Car

5 Women That Shaped the Automobile and the World Around It (and Us)

Automobile retail sales see double-digit growth in February on robust demand