A torque converter is usually referred to as TC or torque converter automatic. It is nothing but a clutch that does not will need a clutch pedal to be operated.

BHPian Indian2003 recently shared this with other lovers.

Quite a few of you know you have a torque converter in your computerized transmission but only a few know what is inside. The torque converter is a piece of intricate engineering. The man who invented the vehicle box must have loved functioning with liquids.

I went about to the trade college I labored at in 2009. A product of my car’s torque converter was built. This, so the learners can see inside of and learn how things perform.

The to start with-calendar year college students created it on their own with some direction.

These kids are exhausted of college and rather of dumping them and giving up, they are supplied a new opportunity to pursue their hobby which is automobiles. They have 4 hrs of principle and 4 several hours of useful operate every working day. At the conclusion of the 12 months, they have to go an examination and then go on a 2-yr apprenticeship at a workshop. Yet another exam afterwards, they grow to be capable master mechanics and unique businesses hold out in line to snap them up.

All but 1 handed in my team in 2009 and today have very well-compensated work opportunities, some of them managing the workshops of diverse car or truck and truck dealers. Most of them continued to function at the very same workshop the place they have been once an apprentice.

The torque converter from the outside the house

The insides

The lock-up equipment, that is a direct connection concerning the motor and the generate axles.

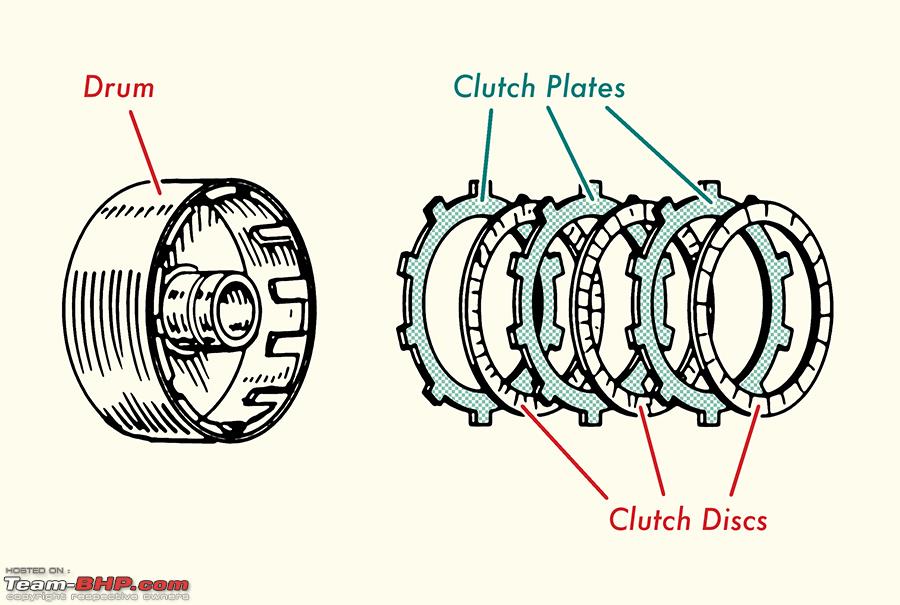

Torque converters have some form of friction plates. In mine, there was a friction disc. All automated boxes have friction plates in housings, as in bikes. The lock-up disc has no friction materials and is locked mechanically by the disc.

The AT is not a suit-and-forget about unit. I have listened to vehicle salesmen propose automated transmissions as upkeep and clutch free of charge but that is a lie or they really don’t have a clue as to what they say.

I was at a Suzuki supplier a handful of months ago to glance at the Ignis for a member of this forum. I questioned about the sizing of the motor, does it have side airbags, how a lot of airbags does the automobile have, and is the 4X4 process a regular mechanical procedure or is it a Haldex procedure.

The man did not have a clue. He considered the Ignis experienced a 3-cylinder engine with sufficient electrical power. He was certain there have been 2 and his companion claimed there need to be facet airbags because the A-pillar was very massive. All he could say about the 4X4 system was that it was really good.

This is what BHPian Guna experienced to say about the subject:

Automatics based mostly on TC also have planetary gears. The torque converter is just the aspect which is enjoying the function of the clutch.

Here’s what BHPian Madrasin_selvan experienced to say about the make any difference:

The torque converter in an AT is utilised to manage the fluid coupling concerning the engine and transmission. This fluid coupling can help in the transfer of power from just one shaft to the transmission shaft.

The transmission shaft leads into the computerized transmission where the planetary gear sets are positioned. For a 6-speed transmission, two planetary equipment sets are functioning in mix, when for an 8-pace, you need to have a single additional equipment established and so on. The clutch discs support in transferring the gear sets, whilst the Transmission Management Module sends alerts in accordance to the throttle enter and driving disorders. The movement of the clutch discs is operated by means of the valve human body (the black shade part) or sump put at the bottom/aspect of the AT.

The torque converter automated gearbox is one large marvel of engineering. The tolerances involved in the AT are so minuscule that even a .1mm modify can lead to oil leakage and effectiveness reduction.

In limited > throttle Input > Transmission Command Module > sends signal as a result of actuators to valve physique > releases fluid to interact or disengage the clutch > planetary gear set moves to increase or lower the speed.

Here’s what BHPian zeng had to say about the issue:

A standard complete Automated Transmission is made up of several person sub-assemblies like:

- Standalone Torque Converter aka fluid coupling which receives mechanical electric power from engine crankshaft/motor flywheel by means of exterior ring gear staying portion of Torque Converter assembly.

- It is a fluid coupling in by itself with or devoid of lockup clutch ingredient transferring ability from motor flywheel to enter shaft of epicyclic equipment established(s) adjacent and outside the house of Torque Converter assembly.

- Torque Converter output shaft would obtain mechanical energy from fluid coupling (with no lockup clutch in procedure) or from lockup clutch set (as and when lockup clutch is place into operation), that’s why, splined to and transfer mechanical power to the input shaft of epicyclic equipment established(s).

The above 3 sub-sets of elements is housed internally in 1 complete housing/assembly as pictured.

- Epicyclic equipment established(s) whose enter shaft receives ability from Torque Converter Output shaft.

- This incoming ability is controlled and directed by sub-assemblies inside of Automatic Transmission Housing like Clutch/piston established assemblies for different speeds of 1,2, R, N and many others., and regulate valve and its actuator system.

The previously mentioned 2 Sub-sets are housed internally inside the transmission housing right adjacent and bolted to Torque Converter Housing/assembly.

- In varying transmission speeds of 1, 2, R, N, and so on., the output shaft of the epicyclic equipment set provides mechanical electrical power to the propeller shaft(s) in the scenario of a RWD or to Front axle half-shafts in the circumstance of FWD.

Just my 2 cents.

Here’s what BHPian KSingh experienced to say about the make any difference:

Just one of the basic and greatest explanations of torque converter I arrived across is provided right here.

The coupling involving the drive and driven shaft is finished through the turbine and impeller (fluid coupling). The torque converter consists of a turbine, a pump/impeller, a stator and a lock-up clutch.

In simple terms, the fluid coupling can be imagined as two table lovers saved experiencing every single other and when a person lover is operated (by an electric powered motor) other will start off rotating without any power input.

Procedure

Stall

The impeller or pump gets the mechanical energy developed by the motor, but the turbine does not rotate since the brakes are continue to utilized.

Acceleration

The brakes are no extended utilized and the acceleration pedal is pressed, as a end result, the impeller rotates a lot quicker and generates torque multiplication doing work in conjunction with the turbine.

Coupling

At this stage, the auto speed has greater, for this reason, the turbine reaches somewhere around 90{7b5a5d0e414f5ae9befbbfe0565391237b22ed5a572478ce6579290fab1e7f91} of the speed of the impeller and the torque multiplication ceases. Modern torque converters use a lock-up clutch to lower the electricity losses inside the coupling fluid by mechanically locking the turbine to the impeller.

This is what BHPian SS-Traveller experienced to say about the make any difference:

Many thanks for bringing this matter up. As well typically, we obtain people referring to automatic transmissions as torque converter automated (TC) vs CVT vs DSG vs AMT.

As discussed higher than, the torque converter is very little but the clutch, devoid of demanding a C-pedal to run it. Now, what is frequently referred to as a TC or torque converter automated (e.g. the Ciaz / XL6 4-speeder), is an automatic gearbox functioning a set of planetary gears (which is a full distinct matter to reveal), linked to the motor as a result of the torque converter.

Just to make clear, the Baleno / Glanza has a CVT (constantly variable transmission) gearbox, BUT it is linked to the engine as a result of a torque converter as perfectly! So technically talking, equally the XL6 and the Baleno automatics are TC automatics – besides that the gearbox is planetary in the previous, and CVT in the latter.

Ring gears are never ever welded, if I might be permitted to stage out a particular technicality once again – they are push-equipped after heating to a certain temperature. After it cools and shrinks, it grips the flywheel firmly. Damaged ring gear teeth will necessitate changing the outer toothed ring only, not the total device.

Look at out BHPian reviews for much more insights and data.

More Stories

Toyota Automatic Transmission: Shifting Gears with Precision

8-Speed Transmission: Navigating the Road to Efficiency and Performance

Add Another One To The Stick Shift List — The 2023 Acura Integra Will Get A Manual Transmission!