Featherweight carbon fiber wheels could have stamps of approval from Ford, GM, and Porsche, but big swaths of the automotive environment continue to be unconvinced they have a great deal of a potential. Fans across the knowledge spectrum from Fb commenters to Gordon Murray imagine their fat financial savings will not justify their extreme price, and that they’re also fragile to use in the genuine entire world.

Ash Denmead, the Engineering and Style and design Director for Carbon Revolution, could not disagree any much more strongly. Not only does he see carbon fiber wheels as a severe challenger to standard alloy wheels, he thinks they raise effectiveness ample to make them critical for almost everything from electric powered automobiles to commercial vehicles. And whilst lots of systems assure to adjust the automobile sector at some undefined afterwards day, he believes the dawn of the carbon age might be only a number of a long time out, Denmead shared in the course of a modern chat with us.

Twitter | @CarbonRev

A Carbon Revolution technician handles a lately made wheel

Denmead’s carbon thread is tethered to Deakin College, in which Carbon Revolution’s manufacturing unit is found currently, and exactly where Denmead spearheaded engineering for his school’s Formula SAE team. In individuals times, he and his classmates utilised handmade fiberglass molds to lay up very small 13-inch wheels to strengthen the performance of their scratch-designed race motor vehicle. In advance of lengthy, their manufacturing abilities grew, enabling them to develop modest batches of prototype wheels, some of which they used on their have private autos. “When I glance back again, it was pretty sketchy,” Denmead remarked.

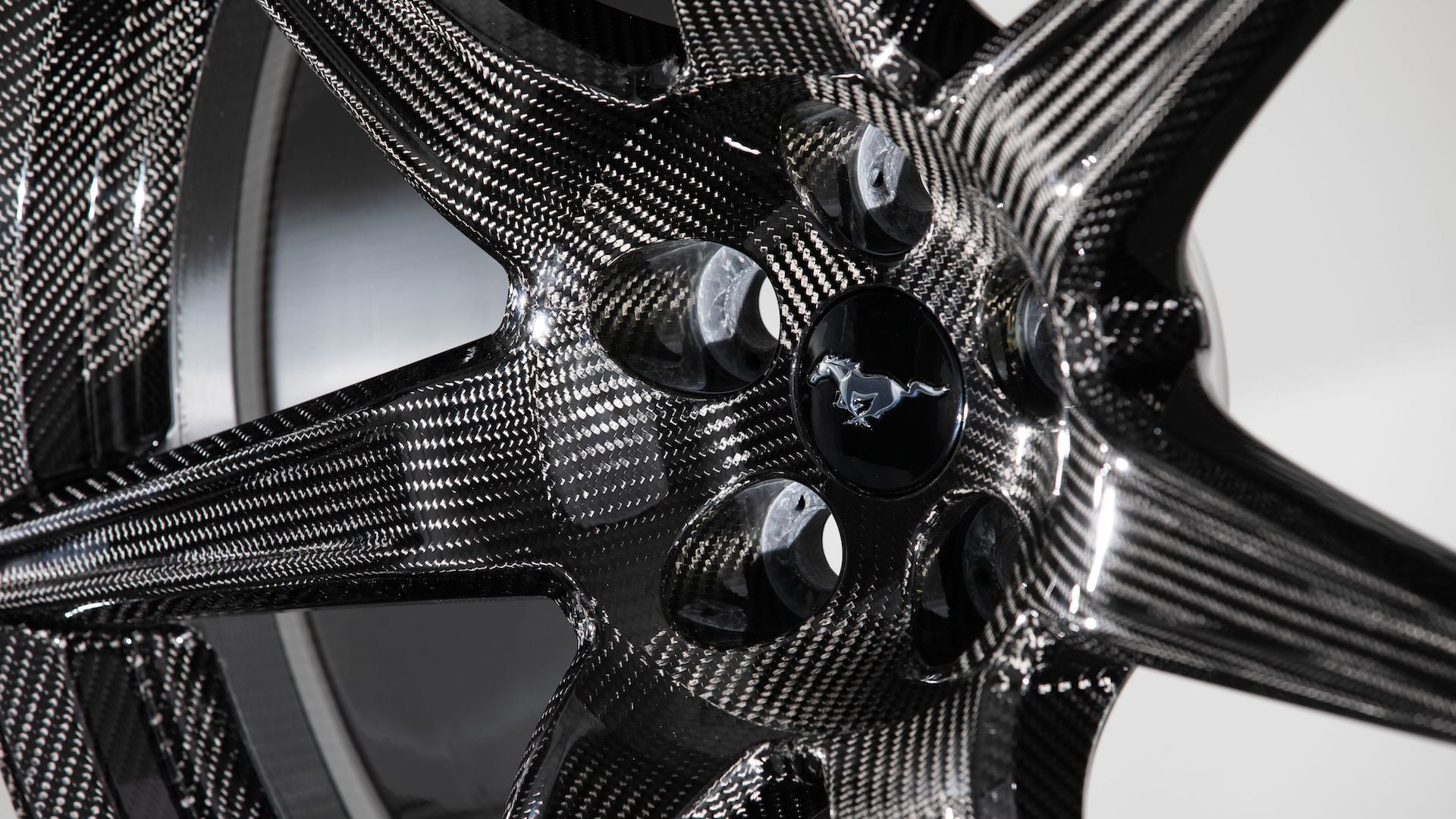

Since then, Carbon Revolution has grown exponentially, and right now supplies the lightweight wheels made use of on tens of thousands of automobiles rolling around North America—from Ferraris and Porsches to the Ford Mustang Shelby GT500 and 2023 Chevy Corvette Z06. Higher-functionality cars, although, are a constrained current market by which the positive aspects of fat personal savings are by now accepted. Denmead is significantly keener about carbon wheels’ likely for far more pedestrian marketplaces, like electric powered motor vehicles.

“You get a multiplier result by reducing mass in a wheel as opposed to decreasing mass in other elements of the auto,” Denmead spelled out. “A lot less vitality to speed the wheel up, considerably less strength to then sluggish it down beneath braking.”

Twitter | @CarbonRev

A Carbon Revolution technician handles a a short while ago created wheel

Less vitality use immediately interprets to increased range, and in turn, effectively hastens recharging as well. And since of its substance houses, carbon fiber’s pounds gain only increases with wheels designed to enhance aerodynamics.

“You can make a truly aerodynamic wheel out of metallic, but when you do that, commonly with metal, the wheel will get truly significant,” Denmead described. That gets specially pronounced on significant-diameter wheels, like the 24-inchers that’ll ship on the Chevy Silverado EV. On aerodynamic wheels of that dimension, carbon fiber can slice fat by up to 45 {7b5a5d0e414f5ae9befbbfe0565391237b22ed5a572478ce6579290fab1e7f91}, depending on how substantially extra toughness the client wishes.

“With carbon fiber, we can do seriously interesting matters and have extremely slender wall structures with hollow sections and achieve that aerodynamic design, or general performance with no the fat penalty,” he continued. “We have received buyers out there interested in 24- and 26-inch wheels as normal fitment on automobiles.”

Ford

20-inch carbon fiber wheels on the 2022 Ford GT Alan Mann Heritage Version

Speaking to their longevity, Denmead understands cracking carbon fiber wheels is nonetheless a frequent fear, but it’s a problem he claims does not fear him in the slightest. “You won’t be able to be frustrated by it,” the engineer mentioned. “The CEO listed here, Jake Dingle, ran [our wheels on] a BMW 320d, and he lives in Melbourne. Every single day he would push 200 kilometers to the manufacturing facility and back again… [and] he will have to have performed that for five many years.”

“There is like 40,000 wheels out there in North The us on the highway, so we are very significantly at the issue exactly where the technology’s verified,” Denmead emphasised.

It really is not just Carbon Revolution’s individual benchmarks its wheels have to fulfill, either. They should move automakers’ sniff tests, for it is they who stand to get rid of buyers more than any issues that could come up. If car companies—some of the most danger-averse firms on the planet—didn’t consider carbon wheels have been all set for primetime, Carbon Revolution would not be in which it is now.

But the journey below has been a prolonged just one, in component owing to the prolonged system of structure and tests every wheel undergoes. Carbon Revolution will take a proposed layout and simulates its effectiveness towards fatigue and impacts, getting into account every little thing down to the style of resin utilized to the route of carbon weave in each and every layer. “Our shoppers are incredibly demanding on the sturdiness screening, so to design and style a wheel and get it into production is usually two to a few-calendar year system,” Denmead spelled out. “So [a] quite intensive style stage, interior simulation of the functionality of the wheel.”

Chevrolet

Optional carbon fiber wheels on the 2023 Chevrolet Corvette Z06 minimize unsprung mass by 41 pounds

Just after achieving sim approval, a slew of genuine-earth tests follows on prototype wheels to guarantee they are far more than up to the endeavor. “We have to pass all of all those checks ahead of those wheels or that wheel layout can get equipped onto a motor vehicle and place on the road.” Then, Denmead says, the automaker performs its possess screening on prototype vehicles—these wheels are living an unseen life of testing, abuse, and far more testing just before they at any time get about to rolling into a customer’s driveway.

It’s this performance-tested, OEM-backed tech that Denmead and his colleagues consider could make EVs leaner, and so greener. Amongst carbon wheels’ weight personal savings and aerodynamic designs, Denmead claims efficiency gains of around 5 percent are feasible. On an EV with 300 miles of assortment, that is an further 15 miles of variety attained by just swapping the wheels out. That could be the variance concerning creating it house or not, or achieving a close by charger. What is extra, it’d also help save clients money, and Denmead is optimistic about the route selling prices are going.

Back again when the firm first started off selling its wheels in the aftermarket, a single of its early customers was Jay Leno, who in a the latest movie on his YouTube channel explained the wheels utilized to expense $20,000 apiece. “We ended up by no means charging $80,000 for a established of wheels. That is just hardly ever, that was by no means the scenario. But it is accurate that the price has reduced drastically over the final 10 several years,” Denmead instructed us.

While the wheels have been expensive—just not that expensive—Denmead agrees that they are coming down in cost, introducing that economical aftermarket carbon wheels—say, $500 a corner—are even now on a sharp decline, and may perhaps be possible by the mid-2020s. “You may be out to 5 yrs away, four or five years absent,” he claimed, citing a want to boost quantity creation.

By then, Denmead expects any trepidation toward servicing cars with carbon fiber wheels will have evaporated as well. Entrepreneurs of motor vehicles outfitted with the presently exotic-seeking wheels have frequently expressed irritation at receiving someone to basically adjust a tire on them, or rotate them. “It can be just a standard immaturity of people’s being familiar with,” the engineer explained. “There’s no variance in switching a carbon fiber wheel to an aluminum wheel, you use the identical devices, you will find movies out there on how to do it. It truly is just, regrettably, persons are a minor little bit fearful of harming an high priced wheel, which is all it is at the moment.” So as the charges go down, he thinks so will tire techs’ unease around carbon wheels.

The applications of this electricity-saving tech are poised to have an affect on a multitude of industries, from personal transportation to shipping and fleets, lowering strength consumption and producing a smaller, but vital dent in the world energy intake of transportation. In the conclude, Denmead says, technologies will march relentlessly on just like it has in the past.

“It is really the identical matter that occurred several years in the past with the trucking business transferring from metal wheels to aluminum wheels,” he concluded. The engineering is undeniable, the cost savings are there, and in Carbon Revolution’s feeling, it really is only a matter of time ahead of everybody clamors to have these lightweight wheels bolted up to their automobiles.

Bought a suggestion or dilemma for the authors? You can reach them in this article: [email protected], [email protected]

More Stories

Investigation launched into complaints of Tesla steering wheels coming off mid-drive | Tesla

Wheels Car of the Year 2023: Finalists revealed!

Why Were so Many Built?